Business process of electronic product solution development

1. Demand

Products exist to meet specific needs. In the early stage of development, we must conduct a comprehensive market research and project feasibility analysis. Therefore, after the user puts forward the demand, the professional engineer team of Weike technology will work with the customer to improve the preliminary analysis, functional parameters and technical indicators of the product. Ensure that the developed products fully meet the needs of users and market.

2. Project initiation

After the requirement analysis is completed, Waco technology refines the project function index from the aspects of CPU selection, power management, function module, system transplantation, driver development, mold design, etc., and conducts scheme demonstration and feasibility analysis again. After confirmation, the requirement list will be made by items and submitted to the user for verification.

3. Sign the contract

After the functions and specific indicators of the project are determined, we will quote according to the difficulty of product development, cycle and personnel input. After negotiation, the development contract was signed.

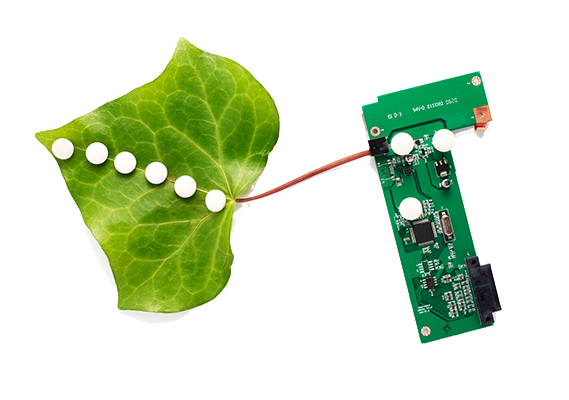

4. Design and manufacture

According to the established scheme, the specific principle design, circuit optimization, PCB wiring, debugging and welding, system transplantation, application testing and other work are carried out. In this process, we will inform the users of the progress regularly and keep full communication with the users. In addition, we will strictly control the purchase of components, PCB manufacturing and welding process to ensure the quality of products. At this stage, we will design several test prototypes.

5. Prototype test

The R & D test firstly tests the prototype according to the function index in the contract to ensure that the function meets the requirements. If not, the design shall be modified until the requirements are met. After the function meets the requirements, temperature test, stability test, anti-interference test, reliability test and endurance test are carried out.

6. Small batch trial production

Small batch trial production is carried out after the prototype test is passed. The number of trial production is decided by the customer. This step is mainly to verify the consistency of the product and the reliability of the channel, and to evaluate the production cycle and possible problems in the process of mass production.

7. Mass production

Formal mass production in the process of small batch production, if there is no problem, then according to customer demand for formal mass production.